Waterproof and Breathable PP/Polypropylene Spunbond Nonwoven Fabric for Agriculture & Vegetable Greenhouse for Weed Control

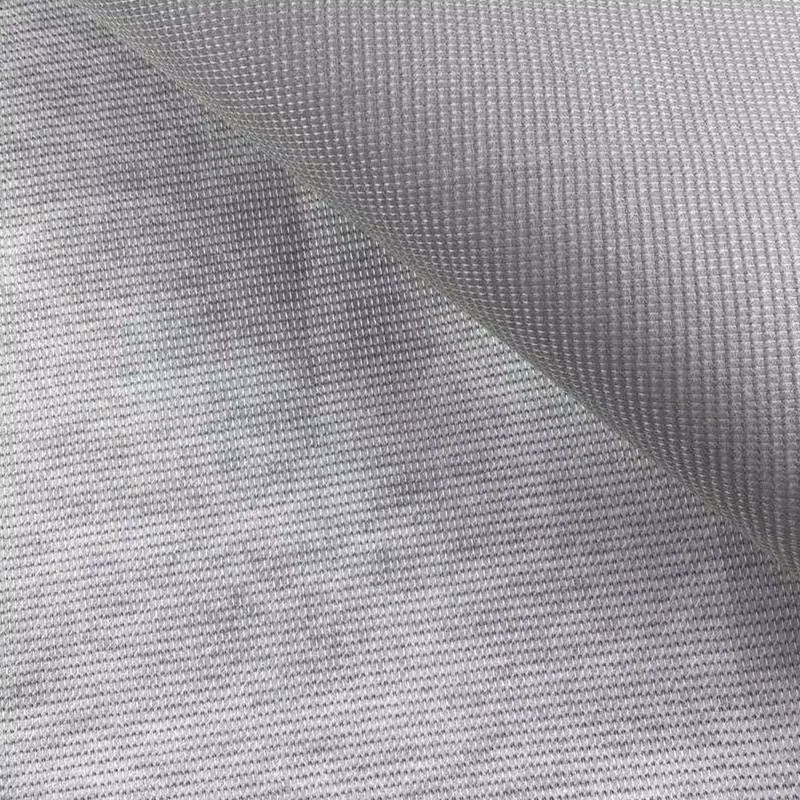

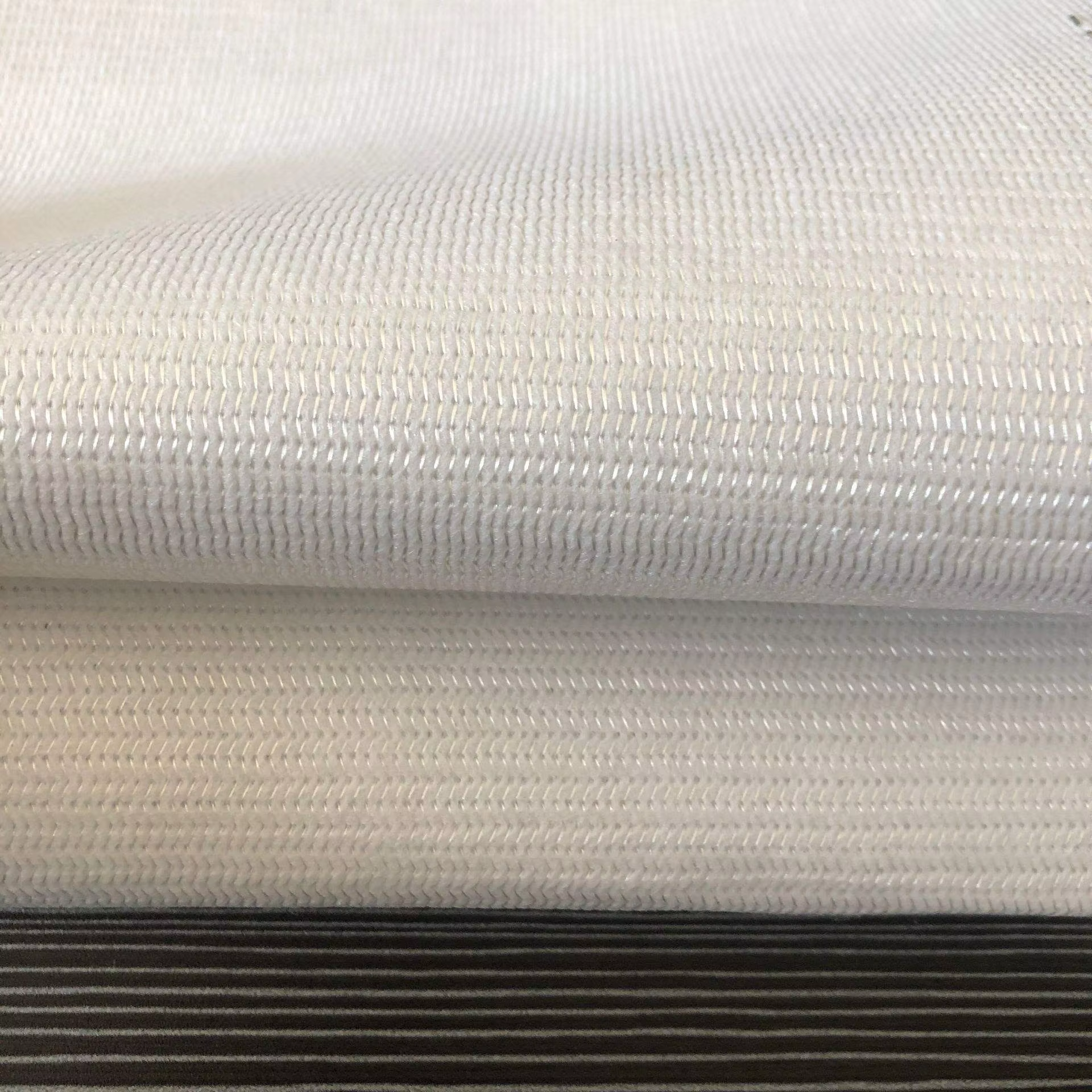

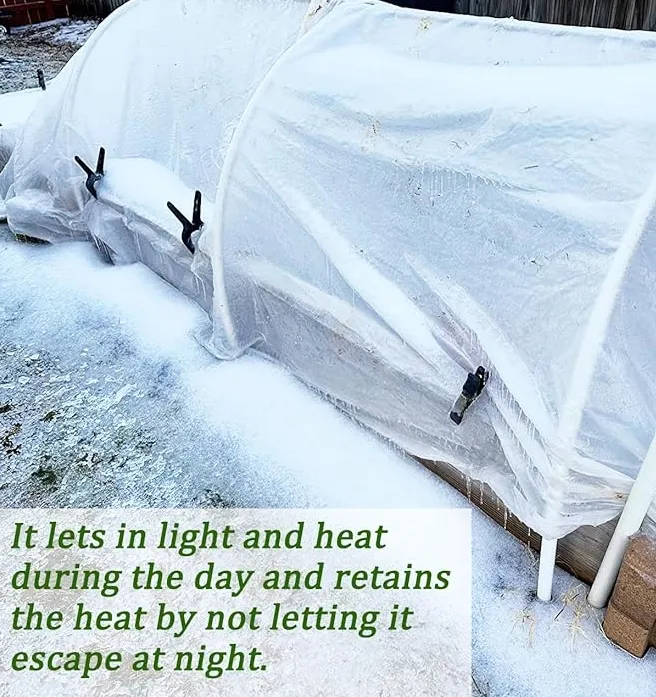

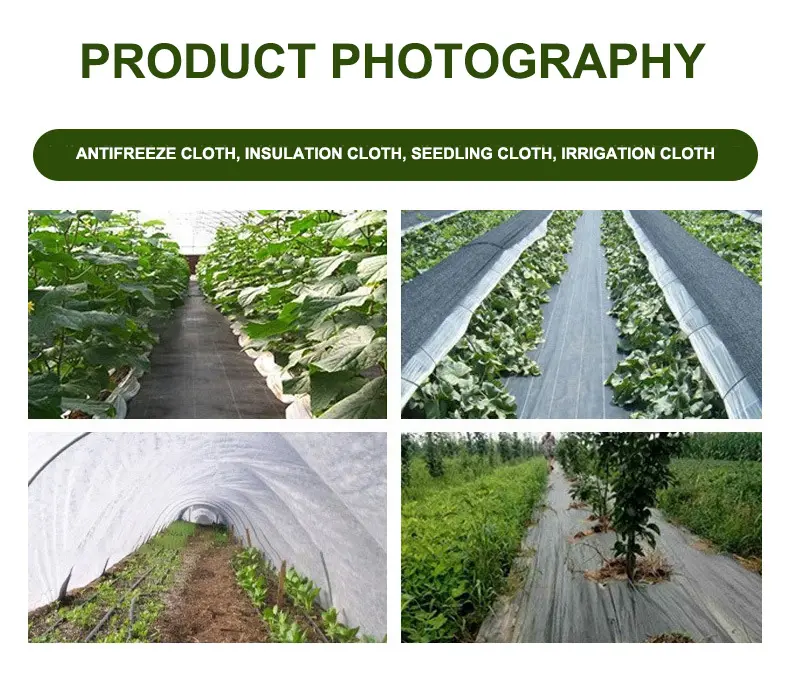

Agriculture nonwoven fabric is a durable, breathable material designed to protect crops and plants from pests, frost, and harsh weather. Made from synthetic fibers, it provides UV protection, prevents weed growth, and allows moisture and air to pass through, ensuring optimal growing conditions. Widely used in horticulture and crop protection, it offers an eco-friendly and cost-effective solution for sustainable farming.

Nonwoven converting refers to the process of transforming nonwoven fabrics into finished products for various industries, such as healthcare, automotive, textiles, and packaging. This process involves cutting, embossing, laminating, coating, and printing nonwoven materials to create functional and customized products that meet specific requirements. Nonwoven converting allows manufacturers to enhance the performance, aesthetics, and utility of nonwoven fabrics, making them suitable for a wide range of applications.

Key Features of Nonwoven Converting:

-

Customization: Nonwoven converting offers the flexibility to tailor the fabric to specific product needs, including size, texture, pattern, and functionality. This customization is ideal for creating products such as hygiene items, medical products, and industrial applications.

-

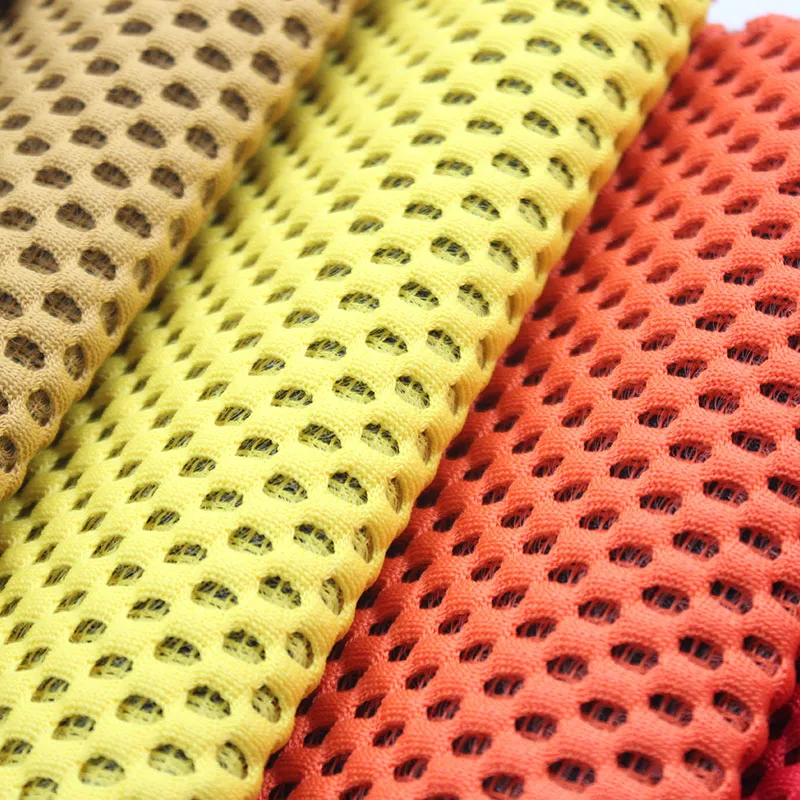

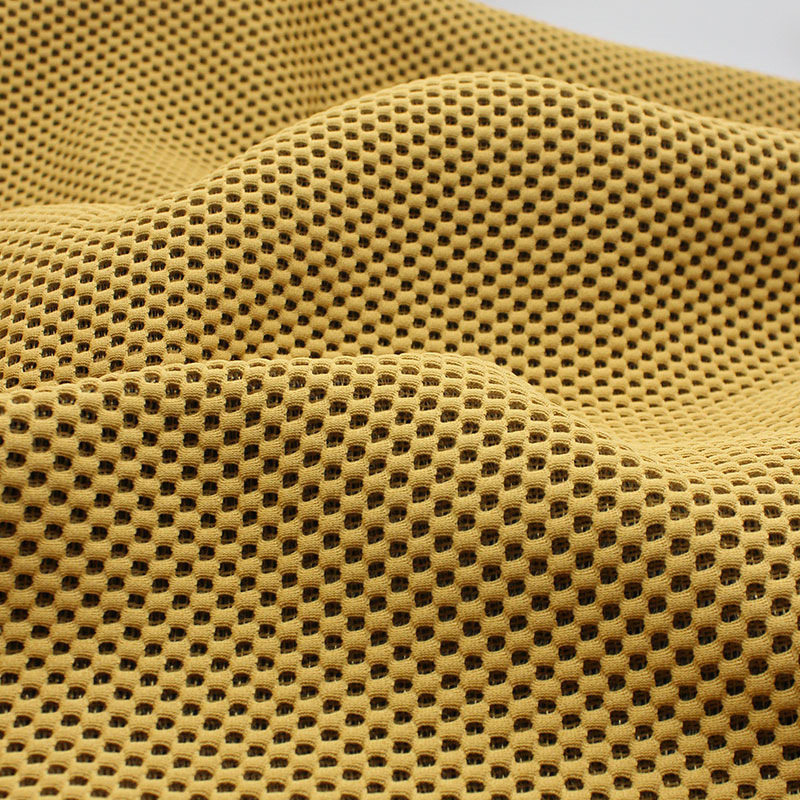

Versatility: The range of techniques used in nonwoven converting allows for diverse applications, from soft and breathable medical fabrics to durable industrial materials. The ability to combine different processes enables the production of multifunctional products.

-

Durability: Nonwoven converting enhances the performance of nonwoven fabrics by improving their strength, resistance to wear, and overall durability. Coatings and laminates can increase the fabric’s resistance to water, chemicals, and other environmental factors.

-

Eco-friendly: Many nonwoven converting processes use environmentally friendly materials, allowing for the production of sustainable and recyclable products. Nonwoven fabrics can be made from biodegradable or recyclable fibers, contributing to reduced environmental impact.

-

Cost-Effectiveness: Nonwoven converting processes are often more cost-efficient compared to traditional textile manufacturing methods, making them a viable option for mass production of low-cost, high-performance products.

Applications of Nonwoven Converting:

- Hygiene Products: Nonwoven converting is widely used in the production of diapers, sanitary napkins, and wipes, offering softness, absorbency, and comfort.

- Medical and Healthcare: The process is used to create surgical drapes, masks, gowns, and wound care products that require high levels of hygiene and durability.

- Automotive: Nonwoven fabrics are converted into soundproofing materials, insulation, and filtration products used in vehicles.

- Packaging: Nonwoven converting is used in the creation of eco-friendly packaging materials such as nonwoven bags, wraps, and protective liners.

- Home Textiles: Converting nonwoven fabrics into products like bedding, curtains, and upholstery offers strength, comfort, and easy maintenance.

Nonwoven converting transforms base nonwoven materials into high-performance, specialized products that cater to various industries. The ability to modify and enhance nonwoven fabrics through converting processes ensures that they meet the functional and aesthetic requirements of modern manufacturing.

|

Item Name

|

Non-Woven Fabric, Weed Mat, Weed Control Mat, PP Ground Cover, PP Non-Woven Fabric, Weed Barrier Fabric, Landscape Fabric, Anti

Grass Cloth, Mulch Fabric, Silt Fence, PP Weed Mat, Weed Barrier, Non-Woven Geotextile |

|

Material

|

PP(Polypropylene) With UV

|

|

Thickness

|

9~250GSM

|

|

Special Treatment

|

Pre-Punched Hole Available

|

|

Feature

|

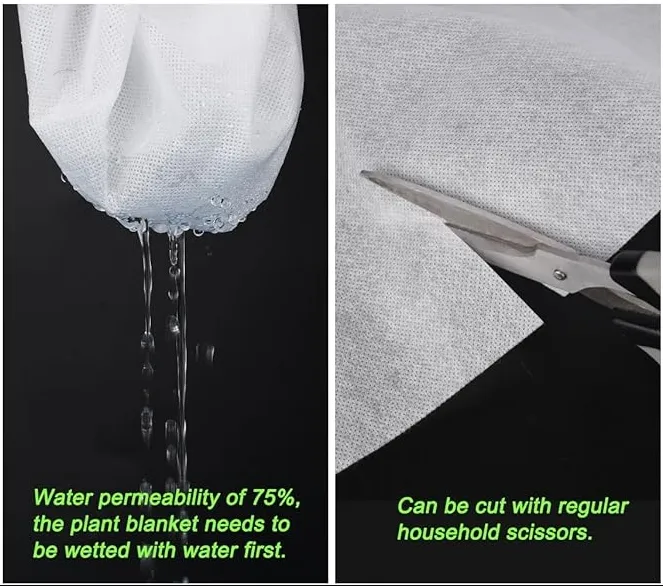

Degradable, good water and air permeability, tear-resistant, eco-friendly, non-toxic

|

|

Size

|

Width: 0.4m, 0.5m, 0.6m, 0.8m, 0.9m, 1m, 1.2m, 1.5m, 1.8m, 2m, 2.5m, 3m, 4m, etc

Length: 5m, 10m, 20m, 50m, 100m, 200m, 300m, 500m, etc |

|

Color

|

Black, White, Green, Black-green, Brown, etc

|

|

Special Treatment

|

Pre-Punched Hole Available

|

|

Packing

|

In Polybag or Box

|

|

Application

|

* Agriculture(50~100gsm): as weed mat to inhibit weed or grass growth, fruit bag, etc;

* Household(50~120gsm): as interlining of furniture, spring mattress, bedding, and suitcase; * Healthcare(10~40gsm): as disposable medical products(such as mask), diapers, etc. |

Leave a Message

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Request an Instant Quote for Your Projects!

If you have specific nonwoven fabric needs or concerns, it’s time to speak to one of our Industry Experts. We’re here to answer any questions you may have and provide guidance on selecting the best fabrics for your projects. Whether it’s for eco-friendly packaging, medical products, or industrial uses, we’re here to help you make informed decisions!