Stitchbond Fabric: A High-Performance Nonwoven Solution for Modern Applications

Introduction: What Is Stitchbond Fabric?

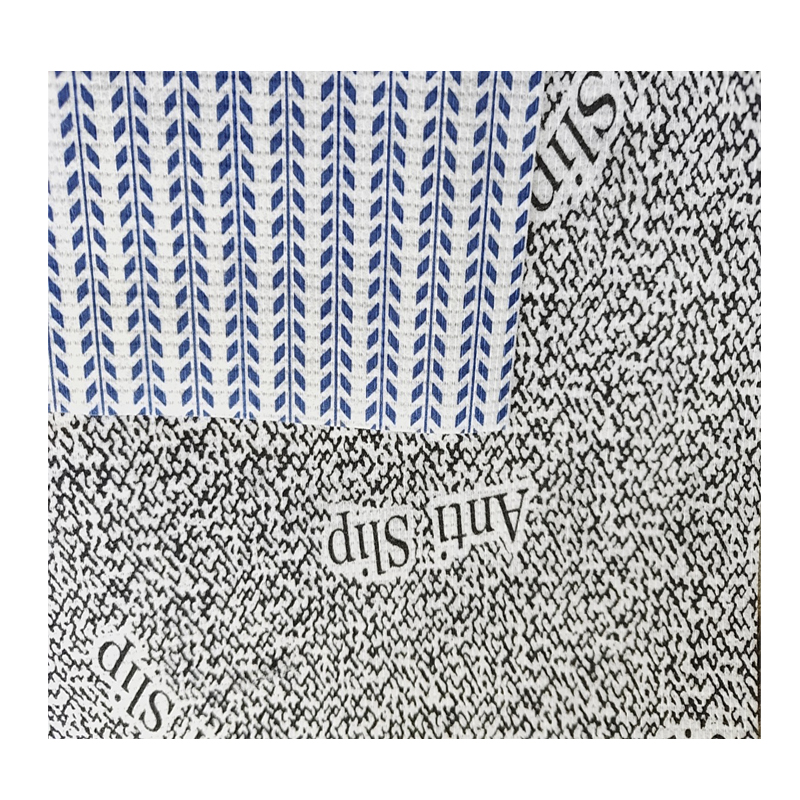

Stitchbond fabric is a mechanically bonded nonwoven fabric created by stitching fiber webs together with continuous yarns. Unlike woven textiles or chemically bonded nonwoven fabrics, stitchbond fabric achieves its strength through mechanical reinforcement rather than adhesives or thermal bonding.

This structure gives stitchbond fabric a unique balance of strength, flexibility, and breathability, making it suitable for a wide range of industrial and commercial uses. In many applications, it serves as a cost-effective alternative to woven textiles while maintaining reliable mechanical performance.

As part of the broader family of technical textiles, stitchbond fabric is widely used in furniture, automotive interiors, packaging, filtration, and reinforcement layers.

How Stitchbond Fabric Is Manufactured

The manufacturing process of stitchbond fabric starts with forming a fiber web, typically made from polyester, PET, rPET, or polypropylene. This web is then fed into a stitchbonding machine, where rows of needles stitch the fibers together using filament yarns.

Unlike spunbond or needle-punched nonwoven fabric, stitchbond fabric relies on controlled stitch density and stitch patterns to enhance dimensional stability. The process allows manufacturers to adjust fabric performance without changing raw materials.

Because no chemical binders are used, stitchbond fabric maintains consistent thickness, clean structure, and stable physical properties, even after secondary processing such as coating or lamination.

Key Performance Benefits of Stitchbond Fabric

High Mechanical Strength with Low Weight

One of the primary advantages of stitchbond fabric is its high tensile and tear strength relative to its GSM. Mechanical stitching minimizes fiber displacement, allowing the fabric to withstand repeated stress and load.

This makes stitchbond fabric especially suitable for reinforcement applications where weight reduction is critical.

Dimensional Stability and Processability

Compared with other nonwoven fabrics, stitchbond fabric offers superior shape retention during cutting, sewing, and quilting. This reduces material waste and improves efficiency during downstream manufacturing.

Manufacturers often prefer stitchbond fabric as a backing or support layer due to its predictable behavior in production lines.

Breathability and Structural Balance

The open fiber structure provides good airflow, positioning stitchbond fabric as a breathable textile solution. While not a traditional mesh fabric, its performance characteristics overlap with mesh fabric in applications requiring ventilation combined with structural support.

Typical Technical Properties (Reference Range)

| Property | Stitchbond Fabric | Spunbond Nonwoven | Woven Fabric |

|---|---|---|---|

| Tensile Strength | High | Medium | High |

| Dimensional Stability | Excellent | Moderate | Excellent |

| Breathability | Good | Good | Limited |

| Cost Efficiency | High | High | Lower |

| Customization | High | Limited | Limited |

Actual values depend on fiber type, GSM, and stitch density.

Applications of Stitchbond Fabric Across Industries

Home Textiles and Furniture

In furniture and bedding industries, stitchbond fabric is widely used for mattress backing, sofa lining, and upholstery reinforcement. Its stability improves product durability while controlling production costs.

👉 Related internal link:

Nonwoven Fabric for Furniture Applications

Automotive Interior Components

Automotive manufacturers use stitchbond fabric for interior linings, insulation layers, and composite reinforcement fabrics. Its resistance to deformation under vibration makes it suitable for long-term use.

👉 Related internal link:

Technical Nonwoven Fabrics for Automotive

Packaging and Reusable Products

Stitchbond fabric is increasingly applied in reusable shopping bags, protective packaging, and industrial covers. Compared with woven alternatives, it offers better cost control and consistent quality.

👉 Related internal link:

Nonwoven Packaging Fabric Solutions

Industrial and Filtration Applications

In industrial environments, stitchbond fabric serves as a support layer for filtration media and coated textiles. Its uniform structure ensures reliable performance under pressure and airflow.

Sustainability: rPET Stitchbond Fabric Solutions

With growing demand for sustainable fabric materials, stitchbond fabric produced from rPET fibers has gained significant attention. rPET stitchbond fabric converts post-consumer plastic waste into durable textile products without compromising performance.

The mechanical bonding process supports sustainability by avoiding chemical adhesives, while rPET fibers help reduce environmental impact. This makes stitchbond fabric suitable for brands pursuing ESG and circular economy goals.

👉 Related internal link:

rPET Nonwoven Fabric for Sustainable Products

Stitchbond Fabric vs Other Nonwoven and Textile Structures

When compared to spunbond nonwoven fabric or needle-punched textiles, stitchbond fabric offers a more balanced combination of strength, stability, and process efficiency.

| Feature | Stitchbond | Spunbond | Needle-Punched |

|---|---|---|---|

| Strength | High | Medium | Medium |

| Stability | Excellent | Moderate | Moderate |

| Breathability | Good | Good | Good |

| Cost-Performance | Excellent | Good | Moderate |

This comparison explains why stitchbond fabric continues to replace traditional materials in many technical textile applications.

How to Select a Reliable Stitchbond Fabric Supplier

Choosing the right stitchbond fabric supplier involves evaluating material consistency, customization capability, and technical support. Stable stitch patterns and accurate GSM control are essential indicators of quality.

An experienced supplier should also provide application guidance, testing data, and long-term supply reliability. These factors are critical for manufacturers seeking consistent product performance.

Conclusion: Why Stitchbond Fabric Is a Strategic Material Choice

Stitchbond fabric combines mechanical strength, breathability, dimensional stability, and cost efficiency into a single nonwoven solution. Its adaptability across industries—from furniture to automotive and sustainable packaging—makes it a future-ready material.

For manufacturers and brands looking to optimize both performance and sustainability, stitchbond fabric represents a practical and scalable textile solution.

👉 Contact us today to request samples, technical specifications, or customized stitchbond fabric solutions.