Production process: The production process of polypropylene non-woven fabrics includes spunbond method, melt-blown method, etc. Among them, spunbonded non-woven fabric is formed by polymer extrusion and stretching to form continuous filament, filament laid into a net, and then made by self-bonding, thermal bonding, chemical bonding or mechanical reinforcement; The melt-blown non-woven fabric is the use of high-speed hot air flow to draw the polymer melt extruded from the spinneret hole of the die head to form microfibers and collect them on the condensate curtain or roller, and at the same time bond themselves.

Fiber diameter: The fiber diameter of melt-blown non-woven fabric is finer, usually its fiber diameter can reach 1 to 5 microns, and the fiber diameter of the melt-blown layer on the mask is close to 1/30 of the human hair; The fiber diameter of polypropylene spunbonded non-woven fabric is relatively thick, and the fiber diameter of the spunbonded layer is about 1/3 of the human hair. Finer fibers guarantee better antimicrobial barrier properties.

Application: The spunbonded non-woven fabric in polypropylene non-woven fabric can be used to make high-grade sports clothes; Melt-blown non-woven fabric due to its small fiber fineness, porosity, fluffy structure and other characteristics, has a good filter, shielding, heat insulation and oil absorption, often used in air, liquid filter materials, isolation materials, absorbing materials, mask materials, thermal materials, oil absorption materials and wiping cloth and other fields. Melt-blown nonwovens in polypropylene nonwovens are also commonly found in medical or thermal materials and other fields.

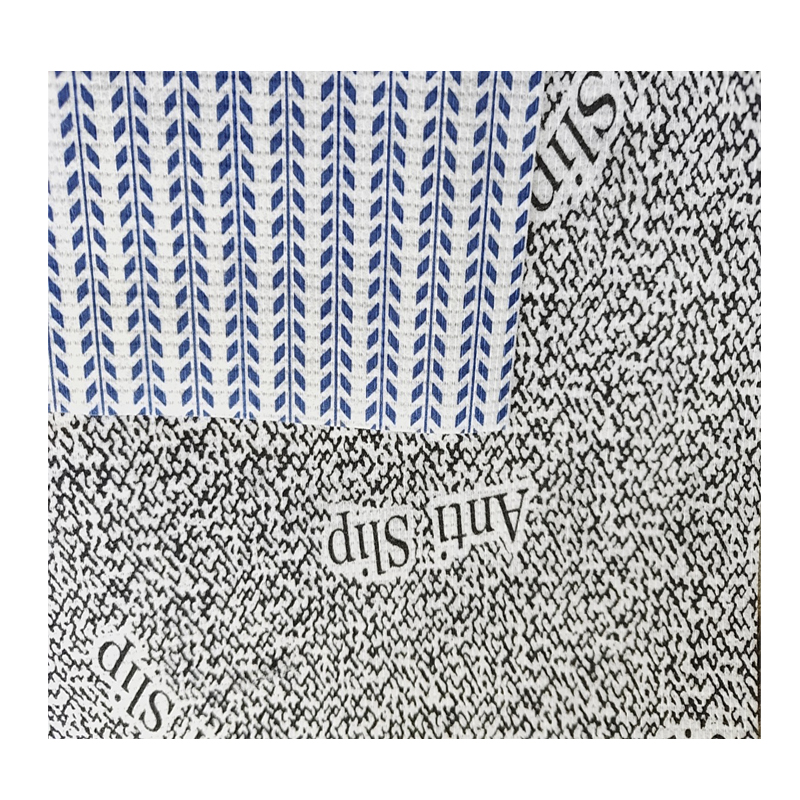

Material characteristics: polypropylene non-woven fabric has the characteristics of light weight, soft, good strength, good elasticity, friction resistance, corrosion resistance, good insulation and warmth, but the heat resistance is poor, dyeing is not easy to wet. Melt-blown nonwovens have many voids, fluffy structure and good anti-folding ability.

It should be noted that polypropylene non-woven fabric is a broad concept, including the use of polypropylene materials through different processes of non-woven fabric; Melt-blown non-woven fabric usually refers to the use of melt-blown non-woven fabric, its raw materials are not necessarily limited to polypropylene, may also use other polymer materials. In practical applications, the specific difference between the two may vary due to factors such as production process and raw materials.