What Fabric is Mesh?

Mesh fabric is a versatile and distinctive textile known for its open, net-like structure that allows for excellent breathability and visibility. It is widely used in various applications due to its unique properties. In this article, we’ll explore what mesh fabric is, how it’s made, its key advantages, and its applications in different sectors.

How is Mesh Fabric Made?

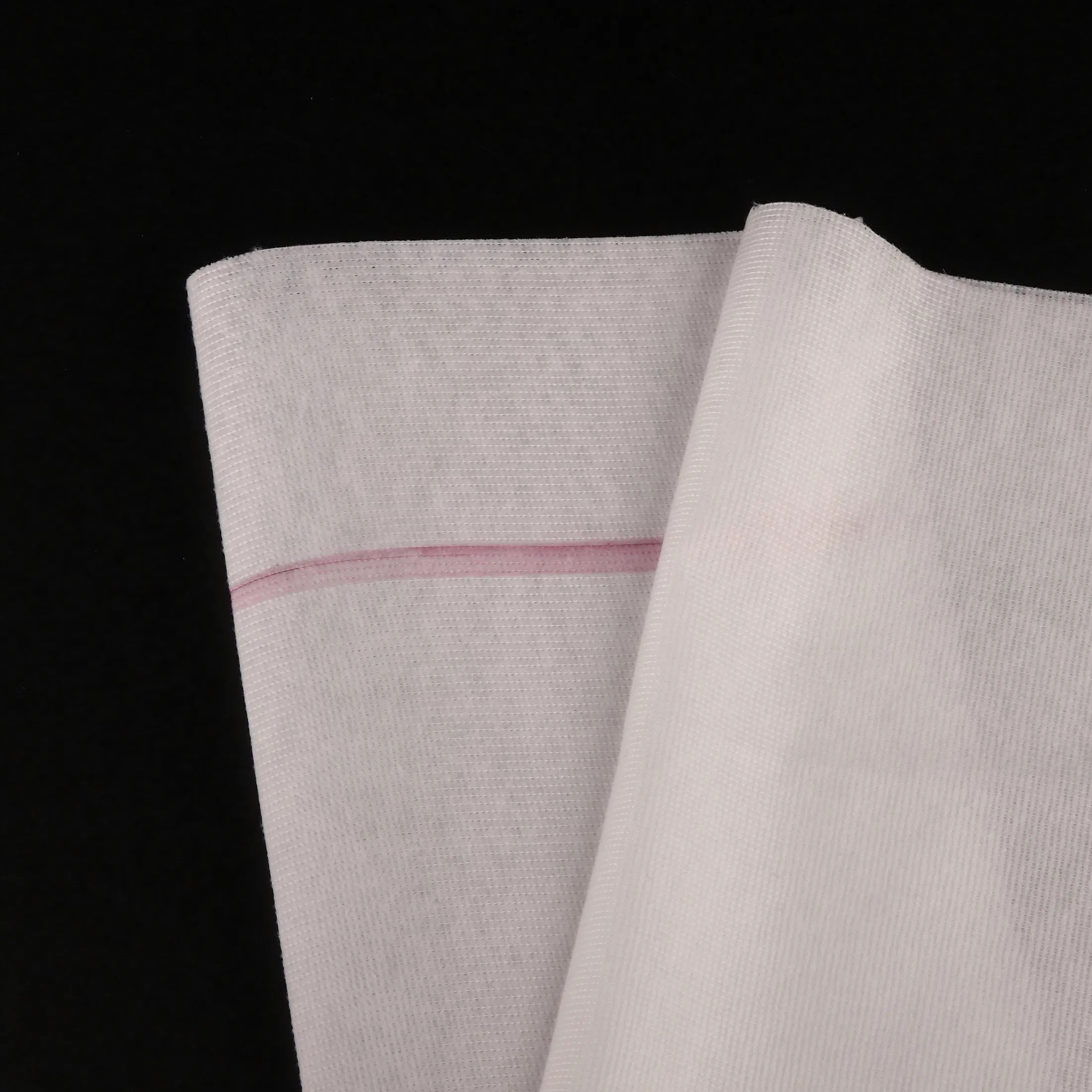

The process of making mesh fabric typically begins with the selection of suitable materials, which can range from natural fibers like cotton to synthetic materials such as polyester, nylon, or polypropylene. The chosen materials are then extruded into threads or yarns that are subsequently woven or knitted into a net-like structure with open spaces between the threads.

The weaving or knitting process creates a fabric with a pattern of interconnected loops or a grid-like structure, which defines the characteristic open nature of mesh. The size of the openings, or apertures, can vary depending on the intended use of the fabric, with some meshes having very small holes for filtration purposes, while others have larger openings for breathability in clothing.

Key Advantages of Mesh Fabrics

Mesh fabrics offer a variety of benefits, making them a popular choice across many industries. Here are some of the key advantages:

1. Breathability and Ventilation

One of the major strengths of mesh fabrics is their breathability. The open structure allows for excellent air circulation, making them ideal for applications where heat and moisture need to be wicked away, such as in athletic wear and outdoor gear.

2. Lightweight and Flexible

Mesh textiles are lightweight and flexible, which contributes to their comfort and ease of movement. This makes them suitable for a wide range of uses, from sports equipment to clothing.

3. Durability and Strength

Despite their open structure, mesh fabrics can be surprisingly durable and strong. The interwoven or knitted structure provides strength and resistance to tearing, making them suitable for industrial applications and heavy use.

4. Versatility and Customization

Mesh fabrics can be customized in terms of aperture size, thread thickness, and material composition, allowing for a wide range of applications from filtration to fashion.

Applications of Mesh Materials

Due to their unique combination of breathability, strength, and versatility, mesh materials are used in a variety of applications. Let’s explore some of the key industries where these fabrics are commonly employed:

1. Athletic and Sportswear

In the athletic and sportswear industries, mesh fabrics are used for making breathable and lightweight garments, such as jerseys, shorts, and sports bras. Their breathability and flexibility enhance comfort during physical activities.

2. Industrial and Safety Equipment

Mesh fabrics are used in industrial settings for safety equipment like gloves, aprons, and masks, where breathability and visibility are crucial.

3. Home Textiles

In home textiles, mesh fabrics can be found in applications such as window screens, outdoor furniture covers, and decorative accents, where their durability and resistance to weather are advantageous.

4. Medical and Hygiene Products

Mesh fabrics are also used in medical applications, such as surgical drapes and wound dressings, where breathability and sterility are important.

Technological Advancements in Mesh Fabric Production

The production of mesh fabrics has seen advancements in recent years, with new technologies allowing for more precise control over the size and pattern of the apertures. This has led to the development of lighter, stronger, and more specialized mesh materials for use in high-performance applications.

Sustainability in Mesh Fabric Production

As sustainability becomes increasingly important in the textile industry, manufacturers are exploring eco-friendly materials and production methods for mesh fabrics. This includes the use of recycled materials and processes that minimize waste and energy consumption.

Conclusion

In conclusion, mesh fabric is a unique and versatile textile with a distinctive open structure that offers breathability, durability, and flexibility. Its wide range of advantages makes it a preferred choice in various industries, from sportswear to industrial applications.

As the demand for sustainable and functional fabrics grows, it’s likely that mesh textiles will continue to play a significant role in the future of textile manufacturing. Whether for athletic wear, industrial safety, or home textiles, mesh fabric offers a practical solution for today’s diverse textile needs.