In the ever-evolving textile industry, innovation and sustainability are key drivers in material development. One such fabric that has gained significant attention for its durability, versatility, and eco-friendly properties is Stitchbond fabric. Whether in the automotive, home decor, or construction industries, Stitchbond fabric has made a substantial impact with its unique manufacturing process and wide range of applications. In this blog, we will explore what Stitchbond fabric is, its benefits, and the many ways it’s being used in today’s market.

What is Stitchbond Fabric?

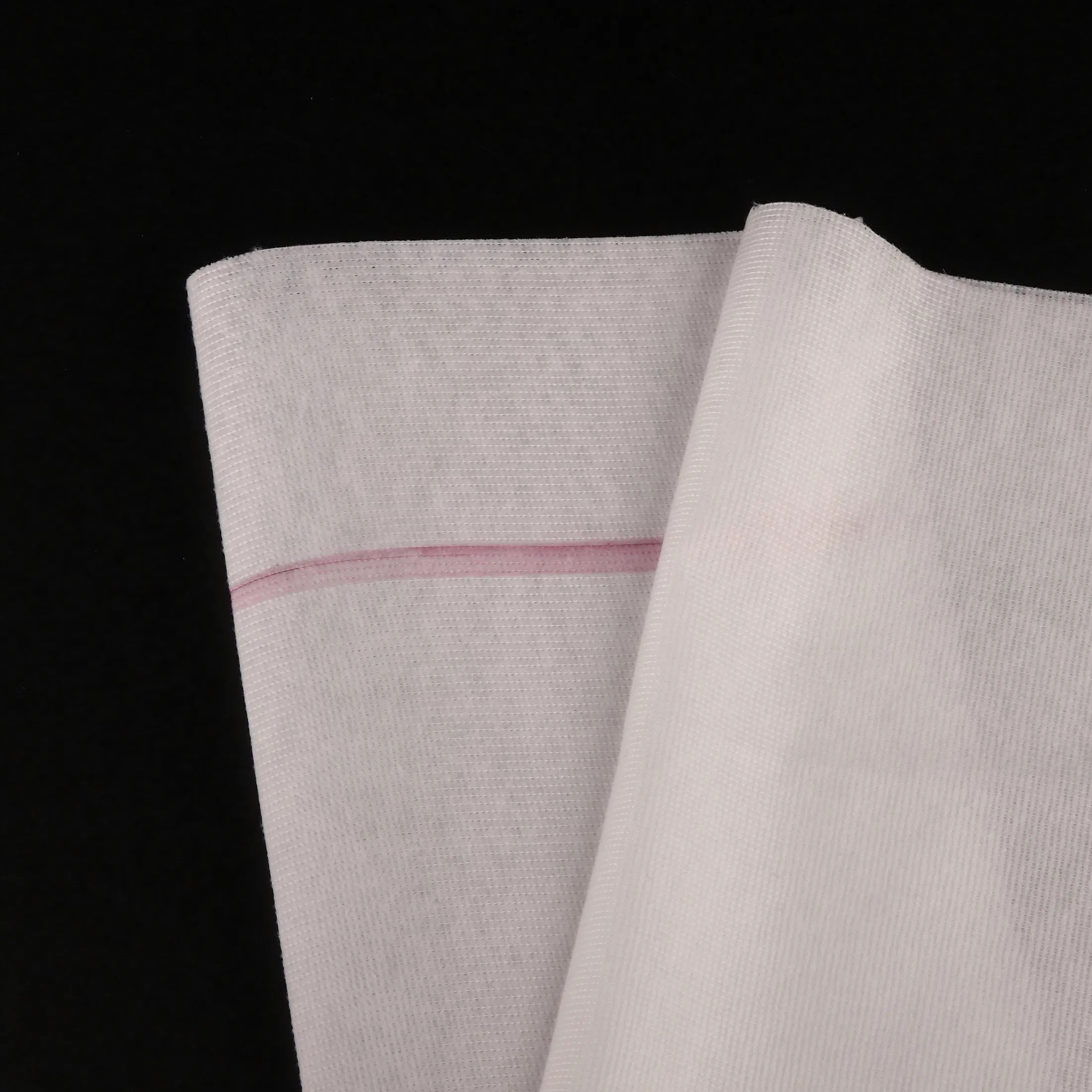

Stitchbond fabric is a nonwoven textile made by bonding fibers together through a specialized stitching process, rather than traditional weaving or knitting. This process involves mechanically stitching continuous strands of fiber into a web-like structure, creating a fabric that is strong, durable, and flexible. Unlike woven or knitted fabrics, Stitchbond fabric is created without the need for yarns or threads to be interwoven. Instead, the bonding fibers are stitched together, which results in a fabric that can be used for a variety of applications across multiple industries.

The Manufacturing Process of Stitchbond Fabric

The creation of Stitchbond fabric involves several steps, starting with the selection of fibers, such as polyester, nylon, or other synthetic materials. The fibers are laid out in a web-like formation and then stitched together using a special needle-punching technique or other stitching methods. The stitching secures the fibers in place, providing the fabric with strength and structure. Depending on the intended use, additional treatments, such as coatings or laminations, can be applied to enhance the fabric’s properties, such as water resistance or fire retardancy.

This innovative bonding process allows Stitchbond fabric to retain many of the qualities of traditional woven fabrics while offering enhanced durability and versatility.

Key Benefits of Stitchbond Fabric

-

Durability: Stitchbond fabric is known for its exceptional durability. The mechanical bonding process ensures that the fabric is strong, tear-resistant, and capable of withstanding harsh conditions. Whether used in automotive applications or as a construction material, Stitchbond fabric offers long-lasting performance, even under stress.

-

Lightweight: Despite its strength, Stitchbond fabric remains lightweight and easy to handle. This makes it ideal for use in a variety of applications where a balance between strength and weight is important, such as upholstery or interior applications in the automotive industry.

-

Eco-Friendly: One of the major advantages of Stitchbond fabric is its potential for sustainability. The fibers used in Stitchbond fabric can be made from recycled materials, and the manufacturing process itself generates less waste compared to traditional woven fabrics. This makes Stitchbond fabric a great choice for businesses looking to reduce their environmental impact.

-

Versatility: Stitchbond fabric is extremely versatile and can be used in a wide range of industries. From automotive upholstery and construction materials to home decor and protective covers, Stitchbond fabric is used in a diverse array of products. Its ability to be tailored for specific applications, combined with its durability, makes it a valuable material for manufacturers across various sectors.

-

Breathability and Flexibility: Unlike some traditional fabrics, Stitchbond fabric allows for breathability due to its nonwoven structure. This makes it suitable for use in products like medical textiles, where breathability and comfort are essential. Additionally, the flexibility of Stitchbond fabric means it can easily conform to different shapes and structures, making it perfect for molded products.

-

Cost-Effective: Stitchbond fabric is often more cost-effective than traditional woven fabrics, especially when considering the lower production costs associated with the stitching process. Its longevity and minimal maintenance needs also add to its cost-effectiveness, making it an attractive option for manufacturers.

Common Applications of Stitchbond Fabric

-

Automotive Industry: Stitchbond fabric is widely used in automotive applications for seat covers, interior panels, and insulation. The durability and resistance to wear and tear make it an excellent choice for automotive interiors, while its lightweight nature helps with fuel efficiency.

-

Home Decor: In the home decor industry, Stitchbond fabric is used for upholstery, curtains, bed linens, and cushions. Its ability to retain its shape and durability under daily use makes it perfect for furniture and home accessories.

-

Construction: In construction, Stitchbond fabric is used for applications such as geotextiles, roofing materials, and protective covers. Its strength and water-resistant properties make it suitable for use in demanding environments.

-

Protective Clothing: Stitchbond fabric is used in protective clothing, such as workwear, safety vests, and industrial uniforms. The fabric’s durability and resistance to wear make it a popular choice in industries where workers need protection from the elements or hazardous conditions.

-

Packaging: Stitchbond fabric is used in the production of strong, reusable bags and packaging materials. Its tear resistance and lightweight nature make it an ideal option for packaging applications that require both durability and ease of transport.

-

Agriculture: Stitchbond fabric is often used in agricultural applications such as ground covers and protective netting. The fabric helps to regulate soil temperature, retain moisture, and prevent weed growth, which is essential for promoting healthy plant growth.

Why Choose Stitchbond Fabric?

Stitchbond fabric stands out for its unique combination of strength, durability, flexibility, and eco-friendliness. Whether you’re in the automotive, construction, or home decor industry, this versatile material offers high performance and sustainability. By incorporating Stitchbond fabric into your products, you can improve product longevity, reduce environmental impact, and create items that meet the growing demand for high-quality, sustainable solutions.

In conclusion, Stitchbond fabric is a valuable and versatile material that offers a wide range of benefits across multiple industries. Its strength, flexibility, and eco-friendly properties make it an ideal choice for manufacturers who prioritize performance and sustainability. As industries continue to seek innovative and environmentally friendly materials, Stitchbond fabric will likely play a critical role in shaping the future of textile applications.