Introduction: Why Resistant Stitchbond Fabric Matters for Your Business

In industries like mattress manufacturing, automotive, and construction, the demand for durable, flame-retardant, and cost-effective materials is rising. Resistant stitchbond fabric stands out as a versatile nonwoven textile that meets these demands. Whether you’re sourcing for a mattress cover stitch bond non woven fabric or non woven stitch bonded roofing fabric, understanding its features will help you make informed purchasing decisions.

📌 If you’re sourcing stitchbond fabric for industrial use, visit our product page for certified, customizable options.

Understanding Stitchbond Fabric and Its Manufacturing Process

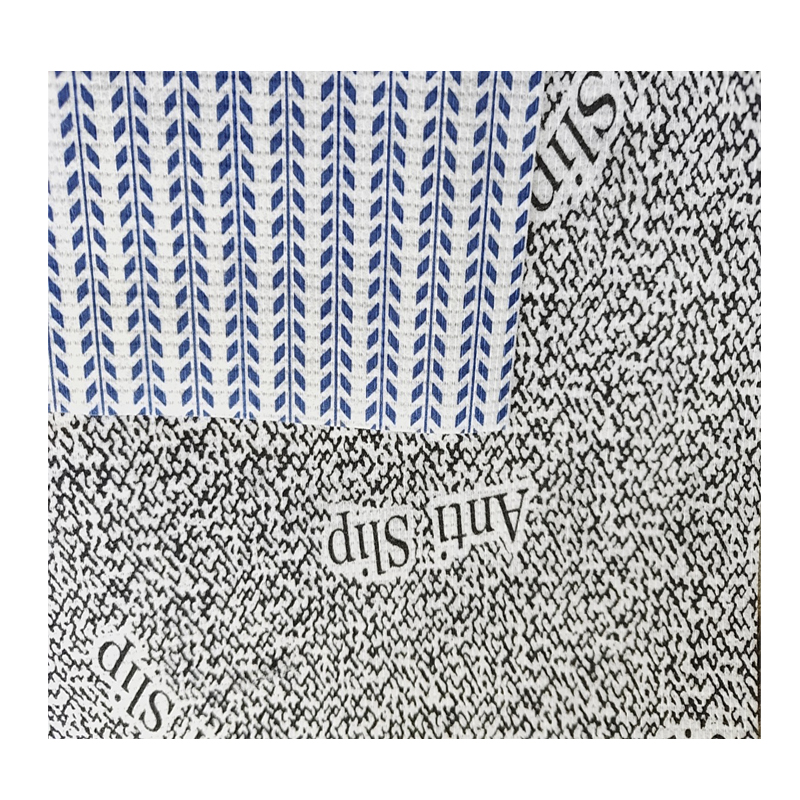

Stitchbond fabric is a type of nonwoven textile created by stitching fiber webs together using warp knitting techniques. Unlike traditional woven fabrics, it doesn’t rely on yarn interlacing but instead uses stitching threads to bond layers of fiber.

This method results in a material that is:

-

High in dimensional stability

-

Durable under stress

-

Available in varying “counts” like 14 count, 18 count, or 22 count stitchbond non woven fabric — indicating the needle density per inch

The use of 100% polyester, RPET fibers, or blends gives rise to eco-friendly options such as bond fabric RPET stitchbond non woven fabric, contributing to sustainability goals.

What Makes Stitchbond Fabric “Resistant”? Key Properties Explained

1. Flame Retardancy

One of the major reasons why buyers choose resistant stitchbond fabric is its ability to meet fire safety standards. Depending on your region or product, you may need compliance with:

-

CFR 1633 (U.S. mattress standard)

-

BS 5852 (UK furniture flammability)

-

MVSS302 (Automotive interiors)

These properties are typically achieved via:

-

Inherently flame-retardant fibers

-

Post-treatment chemical applications

For example, many mattress nonwoven fabric buyers choose black stitchbond fabric made from 100% polyester for fire-barrier use.

2. UV and Weather Resistance

UV resistance is vital for nonwoven stitch bond roofing fabric or any outdoor application. This is often achieved using UV-stabilized polyester fibers and protective coatings. It ensures long-term performance even under direct sunlight or moisture exposure.

3. Chemical and Water Resistance

With proper lamination or surface finishing, stitchbond fabrics can resist oils, acids, and liquids — ideal for protective apparel or technical textiles in chemical environments.

4. Mechanical Strength

Thanks to the unique bonding process, nonwoven stitchbonded fabric demonstrates excellent tensile strength, tear resistance, and puncture resistance — even in lightweight formats. For this reason, it’s often used as nonwoven stitch bond backing in furniture or flooring.

Common Applications of Resistant Stitchbond Fabric

Mattress and Bedding

-

Used in fire-barrier layers and as an outer cover

-

Popular materials: mattress fabric 100% polyester black, double stitch bonded fabric

-

Benefits: breathable, flame-retardant, low-cost

Automotive Interiors

-

Applied in seat backing, trunk lining, and insulation layers

-

Must comply with MVSS302 standards

-

Lightweight yet durable and noise-dampening

Construction Materials

-

Acts as non woven stitch bonded roofing fabric or underlay

-

Water and UV resistant

-

Reinforces bitumen and waterproofing membranes

Furniture and Upholstery

-

Common in inner linings and nonwoven stitch bond backing

-

Flame-resistant and form-stable

-

Aesthetically clean for the back of sofas or headboards

Comparison Table: Stitchbond Fabric vs. Other Nonwovens

| Feature | Stitchbond Fabric | Spunbond Nonwoven | Needle-Punched Fabric |

|---|---|---|---|

| Flame Retardancy | High (with FR treatment) | Moderate | High |

| Dimensional Stability | Excellent | Moderate | Low |

| Strength-to-Weight Ratio | High | Medium | Medium |

| Cost Efficiency | High | High | Medium |

| Surface Appearance | Smooth & uniform | Fibrous & rougher | Textured |

📌 Check our guide on nonwoven fabrics for flame-retardant applications to learn more.

Choosing the Right Resistant Stitchbond Fabric for Your Needs

When sourcing manufacturer stitchbond nonwoven fabrics, ask yourself the following:

-

What is your application?

-

For flame resistance, go with 18 or 22 count stitchbond fabrics

-

For roofing or outdoor, look for UV-treated cross stitch bonded fabric

-

-

What material do you need?

-

100% polyester for strength and cost-efficiency

-

RPET for sustainability and compliance with green standards

-

-

Do you need certifications?

-

Look for suppliers that offer testing reports for BS5852, CFR1633, etc.

-

-

Is custom production important?

-

A good manufacturer should offer options in fabric width, weight (typically 80–220gsm), treatment, and packaging.

-

📌 Explore our custom nonwoven solutions tailored to your industry standards.

Conclusion: Boost Your Product Safety and Value with Resistant Stitchbond Fabric

Resistant stitchbond fabric is not just a cost-effective material; it’s a strategic choice for companies that prioritize safety, performance, and compliance. Whether you’re producing mattresses, car interiors, or roofing materials, choosing the right stitchbond solution can enhance your product quality while meeting global standards.

Its versatility across weights, counts, and treatments—combined with scalable production—makes it a go-to option for procurement teams worldwide.

Call to Action: Let’s Talk About Your Stitchbond Fabric Needs

Looking for reliable manufacturer stitchbond nonwoven fabrics with flame retardant or water-resistant properties?

We offer:

-

Customized widths & counts (14–22 count)

-

Eco-friendly RPET options

-

Certified mattress and roofing fabrics

-

Bulk pricing for B2B buyers

👉 Contact us now for free samples, pricing, and expert support. Let’s build better products—together.