- Home

- Product

- About Us

- Contact Us

- Blog

|

Name:

|

Insole Board

|

|

Size:

|

1.0M * 1.5M or according to customer’s request 120cmNylon / Cotton

|

|

Thickness:

|

0.8-1.25-1.50-1.75-2.0-3mm(other thickness is availbale)

|

|

Color :

|

white or customize

|

|

Feature:

|

Eco-friendly, anti-static, breathable, tear, resistant,recycled

|

|

Applications:

|

Shoes

|

|

Packaging:

|

paper core and PE film wrapped

|

Insole Board is an important part which is widely used in many products.

First, the definition and position of the bottom plate

The midplate is usually located in the middle layer of the product to support, stabilize the structure and provide specific functions. For example, in shoes, the midsole is located between the upper and the sole and is the key part connecting the two.

Second, the material of the bottom plate

In the bottom plate of a variety of materials, common cardboard, fiberboard, plastic and so on. Different materials have different properties:

Cardboard bottom plate: the cost is low, has a certain flexibility and support, but the durability is relatively weak, easy to be affected by moisture deformation.

Fiberboard bottom plate: high strength, not easy to deformation, with good stability and durability.

Plastic bottom plate: light, wear-resistant, with good elasticity and impact resistance.

Third, the role of the bottom plate

Provide support: In shoes, the midsole supports the foot, preventing excessive twisting of the foot while walking or playing sports, reducing the risk of fatigue and injury. In a bag, the bottom plate keeps the bag in shape for easy storage.

Enhanced stability: The bottom plate can increase the overall stability of the product, making it more solid and reliable during use. In shoes, for example, the midsole can be paired with the sole to provide better grip and stability.

Cushioning: Some base plate materials have good cushioning performance, which can reduce the impact of external impact on the body. For example, in sports shoes, the midsole plate is usually made of shock-absorbing materials to protect the foot and joints.

Adjusting comfort: the thickness, hardness and elasticity of the base plate can affect the comfort of the product. By choosing the right material and design of the bottom plate, users can be provided with better wearing or using experience

|

ProductName:

|

Nonwoven Insole board for shoes

|

|

Size:

|

1.0M * 1.5M or according to customer’s request 120cmNylon / Cotton

|

|

Thickness

|

0.8-1.25-1.50-1.75-2.0-3mm (other thickness is availbale)

|

|

Material::

|

Non-woven and Hot Melt

|

|

MOQ:

|

2000 sheets

|

|

Service

|

OEM & ODM are available

|

|

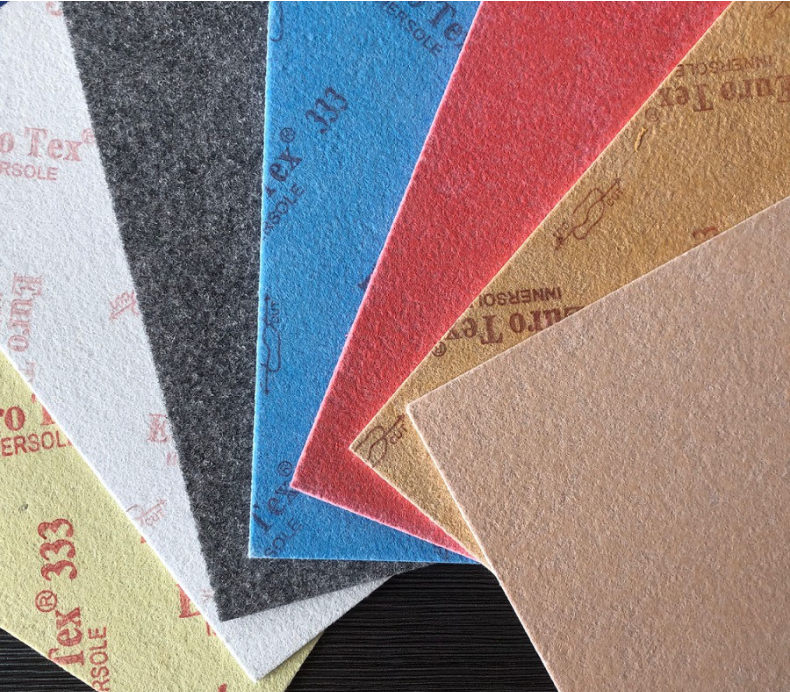

Color:

|

Show as picture or Customizable

|

|

Size:

|

1.0M * 1.5M or according to customer’s request 120cm

|

|

Function:

|

1.The product, with excellent inflection resistant performance, will not be cracked or broken due to inflection, ensuring longer

service life. 2. No leafing will happen with water, suitable for weathering shoes. 3. No deformation will happen due to thermal typeset or other high temperature operation, suitable for modern high speed automatic shoe-making industry. 4. Good fit ability, convenient adhesion, benefit to processing of suitcases and shoes. 5. Made from plant fibers, the product has good air permeability and flexibility, meeting the environmental protection requirement. |

|

Application:

|

1. Shoe industry: Sole forming for various shoes such as leather shoes, sport footwear, leisure shoes and sandals.

2. Case and bag industry: linings for briefcase and suitcase. 3. Stationary: covers for file holder, schoolbag and notebook. 4. Artificial leather: base material for PVC,PU plying-up. |

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

If you have specific nonwoven fabric needs or concerns, it’s time to speak to one of our Industry Experts. We’re here to answer any questions you may have and provide guidance on selecting the best fabrics for your projects. Whether it’s for eco-friendly packaging, medical products, or industrial uses, we’re here to help you make informed decisions!

We will arrange for a specialist to contact you immediately.

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

All of our products are available for sampling