Meltblown Bfe99 Pp Pla Nonwoven Fabric Bfe95 Melt-Blown Fabric 25Gsm Pla Nonwoven Melt Blown Fabric

| PRODUCT ORIGIN | Fujian,China |

| BRAND : | GOLDEN NONWOVEN |

| ITEM NO. : | meltblown 012 |

| SHIPPING PORT : | Xiamen/Wuhan/Qingdao |

| COLOR : | white black red green custom color |

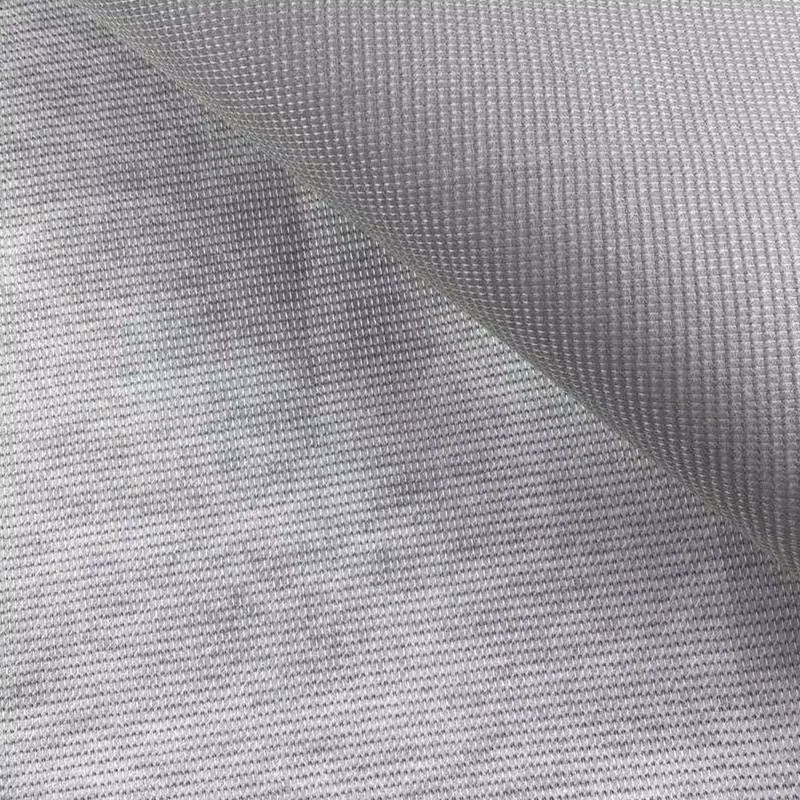

Melt-blown fabric is a kind of nonwoven fabric with a fiber diameter of 1 to 5 microns, which is mainly made of polypropylene with high melting index.

I. Characteristics

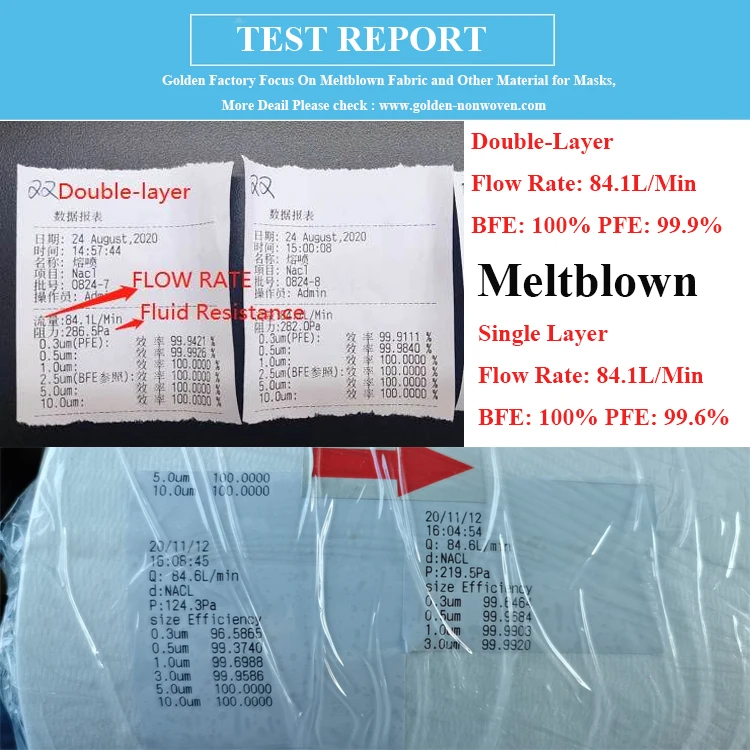

Excellent filtration performance: Due to the extremely fine fiber, melt-blown cloth can effectively filter small particles in the air, such as bacteria, viruses, dust and so on. The filtration efficiency of particles with a diameter of 0.3 microns can usually reach more than 95%.

Strong adsorption: It has a large specific surface area and can absorb a large number of harmful substances and odors.

Good air permeability: While ensuring the filtration effect, it also has certain air permeability, so that people will not feel too hot when wearing.

Soft and comfortable: Soft texture, comfortable in contact with the skin, will not cause irritation to the skin.

Second, the production process

The production process of melt-blown cloth mainly includes the following steps:

Raw material preparation: Polypropylene particles with high melt index are dried to remove water.

Melt extrusion: the dried polypropylene particles are added to the melt-blowing equipment and melted into liquid state by high temperature heating.

Melt-blown mesh: Molten polypropylene is sprayed through the spinneret hole to form a very fine fiber, and stretched and cooled under the action of high-speed hot air flow, and finally formed melt-blown cloth.

Winding: The finished melt-blown cloth is wound up for subsequent processing and use

Meltbown Use

Medical and health field: It is a key material for the production of medical masks, protective clothing, surgical clothing and other protective supplies. It can effectively block the spread of pathogens such as bacteria and viruses, and protect the health of medical staff and patients.

Air purification field: Used in air filters, air conditioning filters and other products, can remove dust, pollen, bacteria, viruses and other pollutants in the air, improve indoor air quality.

Industrial field: In industrial production, melt-blown cloth can be used to make industrial masks, dustproof clothing, filter materials, etc., to protect the health of workers.

Other fields: Can also be used to make sound insulation materials, oil absorption materials, insulation materials and so on.

Features:

High strength, small difference at longitudinal and longitudinal direction .

Acid, non-toxic, non-radiation, harmless to human physiology;

With excellent breathability;

Master batch dyeing, never fade

Smooth, bright color, roll slitting, easy use, best quality

There are two common international standards for the filtration efficiency of melt-blown cloth:

European standard EN 149:2001+A1:2009: The test items mainly include appearance and packaging test, material test, cleaning and disinfection test, practicality test, leakage test, particulate filtration efficiency test, skin affinity test, flame retardant test, dead chamber test, headband test, visual field test, exhalation valve appearance and leakage test, exhalation valve flow test, exhalation valve tension test, respiratory resistance test with exhalation valve, valveless exhalation Suction resistance test, dolomite blocking test, detachable part function test, etc.

Us standard NIOSH (US National Institute for Occupational Safety and Health) certification: For example, the N95 mask is one of the nine types of particulate protection masks certified by NIOSH. “N” means not resistant to oil, “95” means exposed to the specified concentration and particle size distribution of special test particles, mask material filtration efficiency should be ≥95%.

In China, there are also relevant standards, such as GB 2626-2019 “Self-priming filter respirator for respiratory protective Equipment”. These standards make specific provisions on the particulate matter filtration efficiency of melt-blown cloth. Different countries and regions may formulate corresponding standards according to their own needs and actual conditions.

The filtration efficiency of melt-blown cloth is one of its important performance indicators, which directly affects the blocking effect of protective equipment such as masks on particles. In practical applications, it is necessary to select melt-blown cloth products that meet the corresponding standards according to the specific use scenario and requirements

GODLEN MACHINE

4 sets of 1600mm width Single SS spunbond nonwoven machine

1 sets of 1800mm width Double S spunbond nonwoven machine

1 sets of 2400mm width D SingleSSS spunbond nonwoven machine

4 sets of 1600 mm width melt blown nonwoven machine

2 sets of 1600 mm width hot air cotton machine

IPMENT&PACKAGE

Paper tube diameter 3” can choose

Inner rolled by paper tube, outer packed with PE wrap film

Small roll packed with stretch film and carton

1x20FT container can load about 4500 kgs about, 28CBM

1x40HQ container can load about 10000 kgs about ,68CBM

Leave a Message

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Request an Instant Quote for Your Projects!

If you have specific nonwoven fabric needs or concerns, it’s time to speak to one of our Industry Experts. We’re here to answer any questions you may have and provide guidance on selecting the best fabrics for your projects. Whether it’s for eco-friendly packaging, medical products, or industrial uses, we’re here to help you make informed decisions!