In the nonwoven industry, Stitchbond nonwoven fabric stands out for its high strength, dimensional stability, and wide application range. By mechanically stitching fiber webs together, stitchbond technology creates a fabric that combines durability, flexibility, and cost efficiency, making it ideal for industrial and commercial use.

What Is Stitchbond Nonwoven Fabric?

Stitchbond nonwoven fabric is produced by stitching fiber webs with yarns instead of using chemical binders or thermal bonding. This process results in a fabric with excellent tensile strength and structural stability, while maintaining breathability and flexibility.

Stitchbond fabrics can be made from polyester, polypropylene, fiberglass, or blended fibers, depending on the application requirements.

Key Advantages of Stitchbond Nonwoven Fabric

1. High Strength & Durability

The stitched structure provides excellent tear resistance and dimensional stability, even under repeated stress or heavy use.

2. Binder-Free & Eco-Friendly

Because no chemical adhesives are required, stitchbond nonwoven fabrics are low-emission and environmentally friendly, suitable for sustainable manufacturing.

3. Excellent Breathability

The open structure allows air and moisture to pass through, making it suitable for construction, filtration, and insulation applications.

4. Cost-Effective Production

Stitchbond technology allows for high-speed production and material efficiency, making it a cost-effective solution for large-scale industrial needs.

Common Applications of Stitchbond Nonwoven Fabric

Construction & Roofing: Reinforcement layers, roofing substrates, and membranes

Automotive Industry: Headliners, insulation layers, and interior components

Home Textiles: Mattress covers, sofa linings, and upholstery backing

Industrial & Technical Uses: Filtration, insulation, and composite reinforcement

Why Choose Stitchbond Fabric for Your Business?

Businesses choose stitchbond nonwoven fabric because it offers a perfect balance of strength, flexibility, and affordability. It performs well in demanding environments while supporting custom specifications, including weight (GSM), width, color, and fiber composition.

For manufacturers, stitchbond fabric provides consistent quality, stable performance, and scalable production, ideal for long-term supply partnerships.

How to Select the Right Stitchbond Nonwoven Fabric

When choosing stitchbond nonwoven fabric, consider:

Fiber Type: Polyester, PP, fiberglass, or blended fibers

Weight (GSM): Determines strength and application suitability

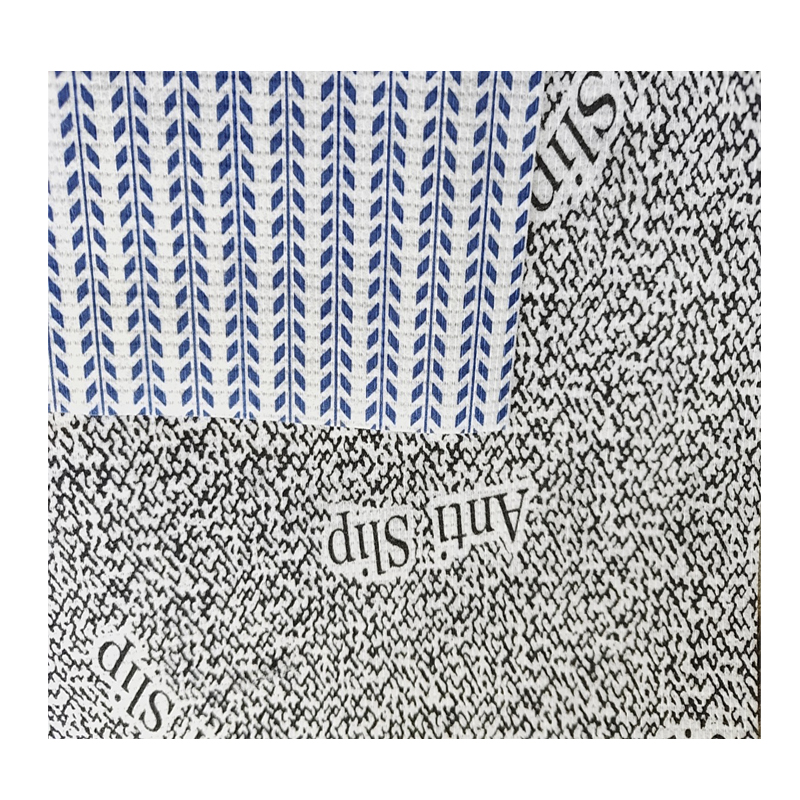

Stitch Pattern & Density: Affects durability and flexibility

End-Use Application: Construction, automotive, textile, or industrial use

Conclusion

Stitchbond nonwoven fabric is a reliable, strong, and versatile material widely used across construction, automotive, home textile, and industrial sectors. Its unique bonding method delivers long-lasting performance while supporting cost control and sustainability.

Looking for a reliable supplier of stitchbond nonwoven fabric?

Contact us today to get customized stitchbond solutions tailored to your application needs.