Green Innovation Drives the Future of Nonwoven Fabrics

With the growing emphasis on sustainability and environmental responsibility, the nonwoven fabric industry is undergoing a transformation—from biodegradable materials to bioactive functional fabrics. Companies are leveraging technological innovation, policy support, and smart manufacturing to enhance both environmental performance and product functionality.

Biodegradable Materials: A Sustainable Direction

Bio-based biodegradable materials are emerging as a key focus. Advanced technologies such as nano/microfiber nonwoven production, biodegradable polymer spinning and web formation, and 3D shaping enable the production of environmentally friendly, functional nonwoven fabrics.

-

Increase the use of natural fibers, regenerated cellulose fibers, and polylactic acid (PLA)

-

Develop biodegradable disposable hygiene products and reusable solutions

-

Implement biodegradable certifications to strengthen international competitiveness

Bioactive Nonwovens: Medical Applications

Next-generation bioabsorbable nonwovens are already used in surgical hemostasis and have potential applications in drug delivery, wound healing, and regenerative medicine, offering high-value solutions for the healthcare sector.

Eco-Friendly Processes: Low Carbon Meets High Performance

-

Ultrasonic Bonding: High-frequency vibration fuses fibers without chemical adhesives, reducing environmental impact

-

Recycled Fiber Low-Carbon Production: Energy consumption is only 10%-20% of traditional chemical recycling, suitable for high-strength applications such as prepreg materials

Policy & Smart Manufacturing Driving Innovation

Under dual-carbon targets and green manufacturing policies:

-

Companies must establish clean production evaluation systems and digitalized, smart factories

-

Promote AI water treatment, intelligent storage, and digital twin platforms for energy efficiency and waste reduction

-

Exporters benefit from GRS/EcoVadis certifications, gaining up to 12% price premiums in EU markets

Technology Trends: Expanding Product Applications

-

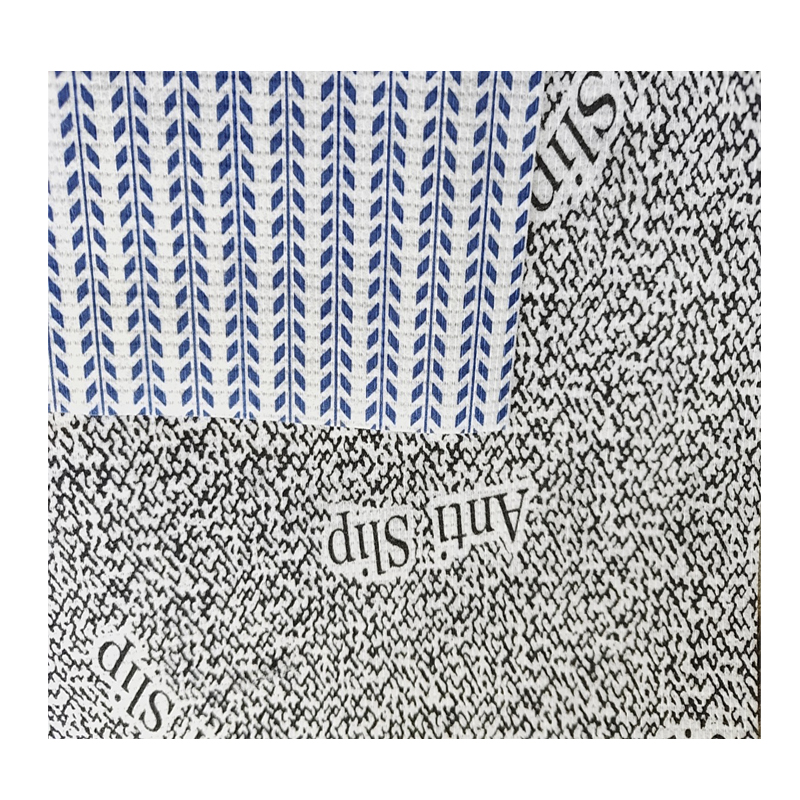

Spunbond & Meltblown Nonwovens: Ultra-lightweight, uniform fibers for masks, protective apparel, and thermal materials

-

Flash Spun Nonwovens: Applications in medical packaging, protective products, and printed materials

-

Electrospun Nonwovens: Used in personal protective equipment, insulation, waterproof-breathable fabrics, and battery separators

-

Eco-Friendly Nonwovens: Full-cotton hydroentangled, dispersible fabrics, PLA and bio-polyester spunmelt, promoting sustainable product industrialization

Industry Challenges & Opportunities

-

High cost of bio-based raw materials requires scale production to reduce costs

-

Certification and standards for biodegradable and recycled fibers are still developing

-

Low textile recycling rates (below 20%) highlight the need for dedicated collection networks

Conclusion: Green High-End Products Driving Growth

By 2025, high-end, eco-friendly nonwoven products are expected to account for over 30% of the industry, becoming a core growth engine for the new materials sector. Companies investing in innovation, sustainable materials, and smart manufacturing will gain a competitive advantage globally.

📩 Interested in biodegradable or bioactive nonwovens? Contact us for samples, technical details, and bulk customization solutions.

This version is:

-

SEO-friendly: Keywords like biodegradable nonwovens, bioactive nonwovens, eco-friendly processes, smart manufacturing

-

B2B-oriented: Emphasizes applications, benefits, and policy advantages

- CTA-driven: Clear invitation to contact for business inquiries