What is the Stitch Bond Method?

The stitch bond method is a revolutionary fabric production technique that has gained considerable attention in various industries. Unlike traditional weaving or knitting, the stitch bonding process uses stitching to bond fibers together, creating a fabric with unique properties. In this article, we’ll explore how this method works, the advantages of stitchbond materials, and its applications in different sectors.

How Is Stitchbond Fabric Made?

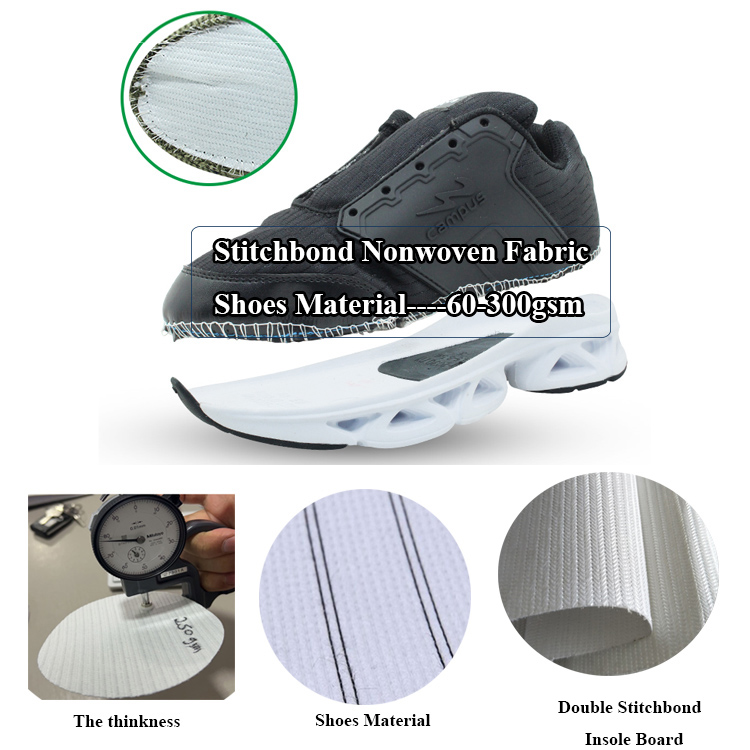

The process of making stitchbond fabric begins with a collection of fibers, usually polyester, nylon, or polypropylene, which are arranged into a nonwoven sheet. Rather than weaving or knitting the fibers, the stitch bonding method involves stitching them together using specialized machines. This technique allows the fibers to be held together securely, resulting in a material that is both durable and flexible.

The fibers are laid out in a sheet, and stitching is done using a needle and thread, which bonds them in a way that is both effective and cost-efficient. This results in a fabric that is strong, lightweight, and versatile—ideal for a wide range of applications.

Key Advantages of Stitchbond Fabrics

Stitchbond fabrics offer a variety of advantages, making them an appealing choice for many industries. Here are some of the key benefits:

1. Exceptional Durability

One of the major strengths of these materials is their durability. The stitching process enhances the strength of the fabric, making it highly resistant to wear and tear. As a result, it’s commonly used in products that require strength, such as automotive interiors and protective clothing.

2. Lightweight and Breathable

Despite its strength, stitchbond textiles remain lightweight and breathable. This makes them ideal for applications where comfort is key, such as medical products and apparel linings. The breathable nature also helps ensure that the material remains comfortable even under demanding conditions.

3. Eco-Friendly Production Process

The production of stitchbond materials is more environmentally friendly compared to traditional textile manufacturing. The technique uses less energy and the materials can often be recycled, which helps reduce the environmental impact of fabric production. Moreover, the reduced reliance on water and chemicals in the manufacturing process contributes to sustainability.

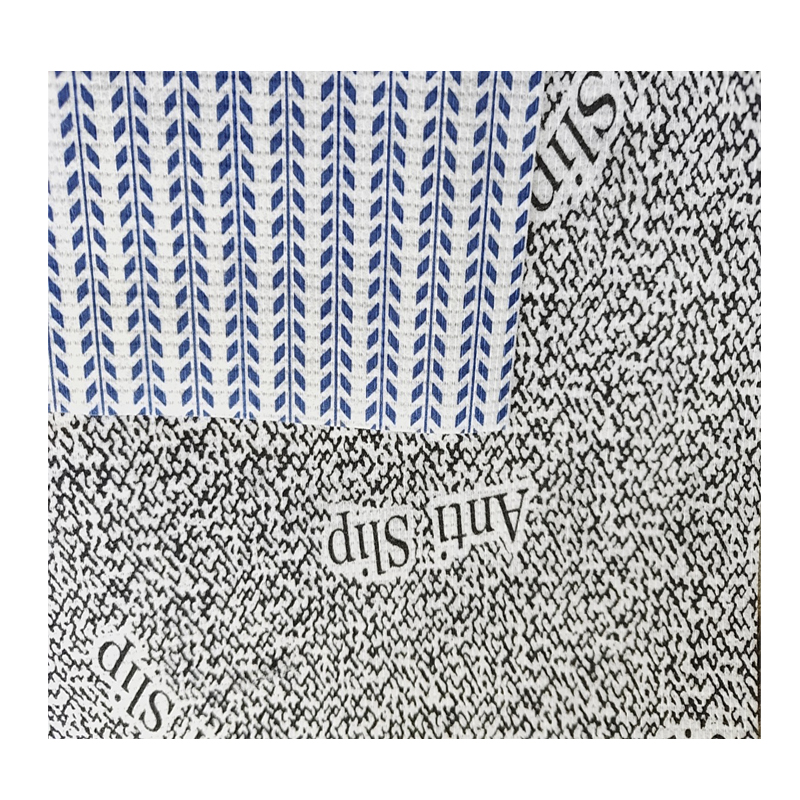

4. Customizable for Various Applications

Another advantage is the ability to tailor stitchbond fabrics to specific needs. Manufacturers can modify the stitch patterns, fiber types, and fabric thickness to create custom materials suited for different industries and purposes, from fashion to healthcare.

Applications of Stitchbond Materials

Due to their unique combination of strength, flexibility, and cost-effectiveness, stitchbond materials are used in a variety of applications. Let’s explore some of the key industries where these fabrics are commonly employed:

1. Automotive Industry

In the automotive sector, stitchbond textiles are often used for making seat covers, headliners, and other interior parts. Their durability and light weight make them well-suited for these applications, where comfort, safety, and longevity are essential.

2. Healthcare and Hygiene Products

These fabrics are widely used in the healthcare industry, particularly in disposable medical products such as surgical gowns, face masks, and sterile sheets. The strength and breathability of stitchbond materials make them an excellent choice for medical environments where hygiene and comfort are critical.

3. Home Textiles

The versatility of stitchbond materials also makes them popular in home textiles. From upholstery and bedding to curtains and wall coverings, these fabrics are customizable in terms of color, texture, and design, offering a wide range of decorative and functional uses.

4. Protective Clothing

Stitchbond fabrics are also used in the manufacture of protective clothing. Their durability makes them suitable for use in industrial uniforms, safety gear, and workwear that needs to withstand tough conditions.

Technological Advancements in the Stitch Bonding Process

The stitch bonding technique has evolved significantly over the years, with continuous improvements in both efficiency and quality. Recent advancements include the use of more advanced machinery, which increases production speed while maintaining fabric strength. Additionally, innovations in fiber technology have led to the creation of lighter and stronger stitchbond materials, opening up new possibilities for their use in specialized applications.

Furthermore, sustainability in the textile industry is becoming increasingly important. As such, manufacturers are researching new, eco-friendly fibers and production methods to ensure that stitchbond fabrics remain a viable option in an environmentally-conscious market.

Conclusion

In conclusion, the stitch bond method is a unique and innovative technique that produces durable, lightweight, and customizable fabrics. With its wide range of advantages, including strength, breathability, and eco-friendliness, stitchbond materials are becoming a preferred choice in a variety of industries, from automotive to healthcare and home textiles.

As the demand for sustainable and versatile fabrics grows, it’s likely that stitchbond textiles will continue to play a key role in the future of textile manufacturing. Whether for industrial applications, fashion, or hygiene products, the stitch bond method offers an effective solution for today’s diverse textile needs.